Add to Cart

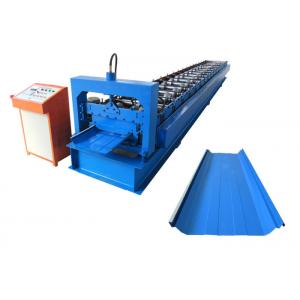

OEM self-lock roof sheet standing seam tile forming machine for metal roofing construction

1. Instruction of the roll forming machine production line

Our roll forming machine can be profile custom,and are lower cost,high efficiency,reliable working ,low energy consumption.we can do any type of equipment according to customer requirements.

This type of forming machine line includes various kinds of roof panel forming machines, wall panel forming machines, and lining plate forming machines , C Z purlin roll forming machines, guard rail roll forming machines, metal deck roll forming machines, guide rail roll forming machines etc. It has received 3 patents of utility model and is widely used in steel construction enclosure. We can provide roll forming equipment in various profile shapes and configurations to satisfy your specific requirements.

The components that each set machine includes:

| Hydraulic decoiler ( 5 Tons ) | 1 unit |

| Main Roll Forming Machine | 1 unit |

| Cutting Device | 1 unit |

| Electrical System with PLC Control | 1 unit |

| Hydraulic station | 1 unit |

| Auto stacker | 1 unit |

2. The roll forming machine parameters

| Raw material | |

| Processing material | Color steel coil, Galvanized coil, Aluminized zinc coil or as your customized |

| Processing thickness (mm) | 0.3-1.2mm or as your customized |

| Material of rollers | High grade 45# steel, Processed by CNC lathe, Hardening and tempering, polishing, hard chrome plated 0.05-0.07mm |

| Material of shafts | 45# steel |

| Machine details | |

| Diameter of shafts | 60mm or as your customized |

| Forming speed | 20-25m/min or as your customized |

| Under frame | 300 H-beam |

| Sidewall | 16mm |

| Connect bar | 25mm, zinc plated |

| Forming steps | 10-18 or as your customized |

| Control system | Delta PLC and Inverter |

| Suitable power | 380V, 50 Hz, 3 phase or according to your need |

| Drive mode | Chain and sprocket, chain size 1 inch |

| Main motor | 4kw |

| Hydraulic pump station | 4kw |

| Cutting model | Hydraulic profile cutting |

| Weight of the machine | 2 ton -4 ton |

SHITONG was established in 2005. Our company is a comprehensive enterprise integrating production, sales and services and tranding in all kinds of machinery. We are mainly devoted to the development and manufacturing of metal plate cold bending roll forming equipment.

We have high quality professional teams, skillful talents,strong technical force,strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system.

4. Features of the roll forming machine production line

- The production size we can design the machine all as customize,customer just show us the profile drawing material thickness width, we can design the machine according as the request

- When we finish the machine, we will test the machine and adjust the machine many times to be sure the machine have a perfect status and when customer receive the machine, the machine can be used very easy.

5. Roll forming machine pictures:

6. FAQ

Q1, If our country's voltage is different from yours, how to solve that?

A1, The usual voltage is 380v,220v,415v. If yours are not one of them, we will design the electric motor to suit your voltage.

Q2, What can you do if the machine broken?

A2, Our machine's warranty period is 1 year,

if the broken parts can't repair,we can free send the new parts replace the broken parts to you except the solenoid valve,the solenoid valve you must pay the express cost yourself.

if after warranty period,we can through negotiation for to solve the problems,and we supply the technical support for the whole life of the equipment.

Q3, How can we be assured that you will deliver us quality machine with spare parts?

A3,1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.